Call: 231-529-6271

Email: Quality@haleman.com

PRODUCTS

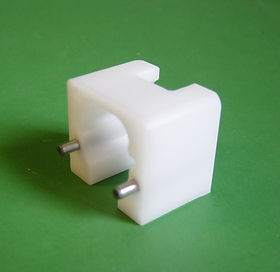

Continuity testing fixtures are used for testing circuits and confirming correct location and position of terminals in connectors. Some fixtures are used on wire harness assembly lines, some for EOL testing; others are ergonomically designed for hand-held convenience and quick testing of mounted connectors.

Depending on customer needs, our fixtures may be mounted on a test board, an assembly jig, or hand-held. Connectors are easily inserted, securely held in place, and quickly removed after testing. Spring-loaded compliant contact pins electrically check circuits and do not violate terminals. Switch probes are installed as required for the detection of clips, bolts, nuts, gaskets, internal and external secondary locks. Fixtures are designed to seat the wedge, or TPA, when connector is fully locked in the correct testing position. Unlocked terminals and missing secondary locks are detected in well-designed continuity testing fixtures when original connector design allows access. Our test fixtures have a typical life cycle of at least 500,000 to several million test cycles depending on routine maintenance and replaceable parts.

Hale Manufacturing uses only highest quality materials and components without compromise. All parts of our test fixtures are replaceable.

We utilize conventional and CNC equipment with CAD/CAM accuracy and flexibility. Our standards assure customers and end-users of superior products.